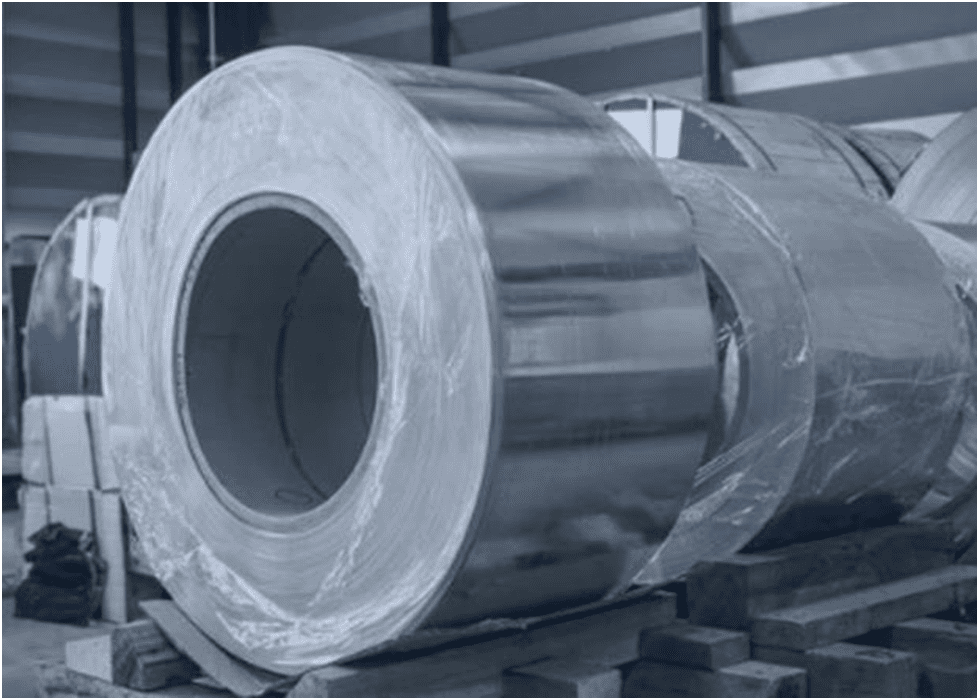

Nickel alloy fabrication is the process of creating useful products using different types of nickel-based materials. These materials are known for their exceptional properties such as corrosion resistance, high-temperature stability, and strength. Hence, its fabrication involves various techniques to transform raw nickel alloys into finished products, catering to diverse industrial needs.

Types of Nickel Alloys:

Nickel alloys come in various types, each with distinct characteristics suitable for specific applications. Some common types include:

- Inconel Alloys: Known for their high-temperature resistance, Inconel alloys are often used in aerospace and gas turbine industries.

- Monel Alloys: These alloys are resistant to corrosion and acidic environments, making them suitable for marine engineering and chemical processing.

- Hastelloy Alloys: Hastelloy alloys excel in harsh environments ikat fabric involving strong chemicals, making them ideal for chemical processing plants.

Nickel Alloy Fabrication Techniques:

Several fabrication techniques are used to shape nickel alloys into functional products:

- Welding: Welding is a common technique used to join nickel alloy components. Techniques like TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding are utilized.

- Machining: Machining involves cutting, shaping, and finishing nickel alloy parts using machine tools. It is used to create custom machined fasteners and intricate components.

- Forming: Forming techniques like bending and forging are used to reshape nickel alloys without cutting. This is particularly useful for creating custom pipe spools.

- Casting: Casting involves pouring molten nickel alloy into molds to create complex shapes. It’s useful for producing components with intricate designs.

Applications of Nickel Alloy Fabrication

It finds applications in various industries due to the unique properties of nickel-based materials. Some key applications include:

- Aerospace Industry: Nickel alloys are used to create parts for aircraft engines and components that need to withstand high temperatures and stress.

- Oil and Gas Sector: The corrosion resistance of nickel alloys makes them valuable for pipelines, valves, and other equipment in offshore and onshore oil and gas operations.

- Chemical Processing: Nickel alloys are utilized in chemical plants to construct reactors, containers, and pipes that handle corrosive chemicals.

- Renewable Energy: Nickel alloys play a role in renewable energy systems such as solar power and fuel cells due to their high-temperature stability and resistance to oxidation.

Role of Custom Pipe Spools Fabricators

Custom pipe spools fabricators specialize in creating tailored pipe configurations for specific industrial needs. They use nickel alloy fabrication techniques to design, assemble, and weld pipe spools according to project requirements. These fabricators ensure precise measurements, proper welding, and adherence to safety standards.

Role of Custom Machined Fasteners

Custom machined fastenersare essential components in various industries, ensuring the secure assembly of machinery and structures. Nickel alloy fabrication is employed to create fasteners with specific dimensions and threading, providing optimal fit and function.

Concluding Lines:

In conclusion, nickel alloy fabrication is a versatile process that transforms nickel-based materials into valuable products with unique properties. Custom pipe spool fabricators and custom-machined fastener producers contribute significantly to the fabrication process, meeting the specialized needs of different projects. As technology advances, this fabrication continues to evolve, driving innovation and efficiency in various sectors.